lars

Well-known member

- Joined

- Feb 15, 2003

- Messages

- 209

- Location

- In my workshop bar in Denver

- Corvette

- 64 Black Roadster; 85 Coupe; 09 G8 GT 4-door Vette

In a reply I did in the Topic Post “Rochester Q-Jet Setup”

(http://www.corvetteactioncenter.com/forums/c3-technical-performance/130172-rochester-qj-set-up.html)

tracksnblades1 had some doubts about the Q-Jet’s abilities compared to Holley-based designs:

I just finished up another dyno test of a mildly-built 400, and the results follow…

The engine was a stock-block 400 with stock factory cast iron heads. I got compression ratio up to 10.08:1 with flat-top pistons and the stock deck height. The bottom-end was kept stock with some good rod bolts, and the heads were given a good 3-angle valve job. The restrictive EGR intake was scrapped and an Edelbrock “Performer” intake was used to keep overall engine height near-stock so that there would be no hood interference problems. The owner wanted a very mild cam to maintain engine vacuum and power brakes, so a mild hydraulic roller was used. No other trick parts – the engine was pretty much a modest compression 400 with a mild roller in it.

The real purpose of the dyno run was to get good numbers for the owner and to get a good tune on the engine, but we also wanted to get a back-to-back comparison of a well-tuned Q-Jet to a properly set up Holley of similar size. Those results came in as expected…

For the first “out-of-the-box” dyno pull, the Q-Jet was used (17056263). This carb is factory jetted at 70/42/DB, which is awfully lean. I re-jetted the carb to 76/42/DB with a 3/8” float level and .640 secondary rod height. Other carb tuning and parameters were set up exactly as outlined in my Q-Jet Tuning Paper under the “Quickie Performance Setup” section.

After getting the timing optimized (the inefficient chambers in the iron heads took 41 degrees total timing for best power and torque without detonation – an increase from my initial setting of 37). We were using 91-octane pump gas with 10% ethanol – right out of the gas station down the street. Total timing was coming in before 2000 rpm – a very quick curve.

The 4 initial pulls we did on the engine showed a “dip” in the torque curve (with resulting “sag” in the power curve) between 3500 and 4000. This is right where the Q-Jet secondary airvalve is starting to open up, and the air/fuel numbers were showing a lean condition right at the tip-in of the secondaries. The stock “DB” secondary rods in the carb have the “short” power tips, which delay fuel enrichment. We installed a pair of Edelbrock “CL” rods which have about the same diameter (just a small tad richer), but they have the “long” power tips. Richening up the secondary tip-in point really flattened out the torque curve and made the power curve a near straight-line shot towards the top.

Once this had been sorted out and the Q-Jet was correctly tuned, I wanted to do the final run just to prove one of my pet-peeve points: Q-Jets are garbage, and any Holley will outperform a Q-Jet… blah, blah, blah… As I state in all my seminars and papers, a properly tuned Q-Jet will perform almost identical to a properly tuned Holley, except that the Q-Jet tends to produce better torque and throttle response in the low and mid range in a street driven vehicle than the Holley. Now that we had our Q-Jet pretty well dialed in, it was time for a switch to the Holley.

The Holley I selected was a 3310-1, which is a 750 vacuum secondary with the secondary metering block (not the cheap plate). The carb was set up and tuned to spec with 72 primary jets, 80 secondary, and the “tall yellow” secondary spring was selected to assure that the secondaries would actually open. Choke system was removed to give it all the airflow advantage it could get. Float levels, shooters, and all tuning parameters were all set up correctly and verified and “blessed” by noted NASCAR engine builder Steve Yacki (who was also our dyno operator this day). The Holley was given 2 pulls on the dyno, and we verified that the air/fuel ratio on the Holley was virtually identical to the Q-Jet: The A/F numbers matched exactly at many data points, and were never different by more than 0.5:1 at any time through the entire rpm range – the 2 carbs were metering air and fuel at exactly the same ratio, so there was no “fudging” any numbers on these pulls.

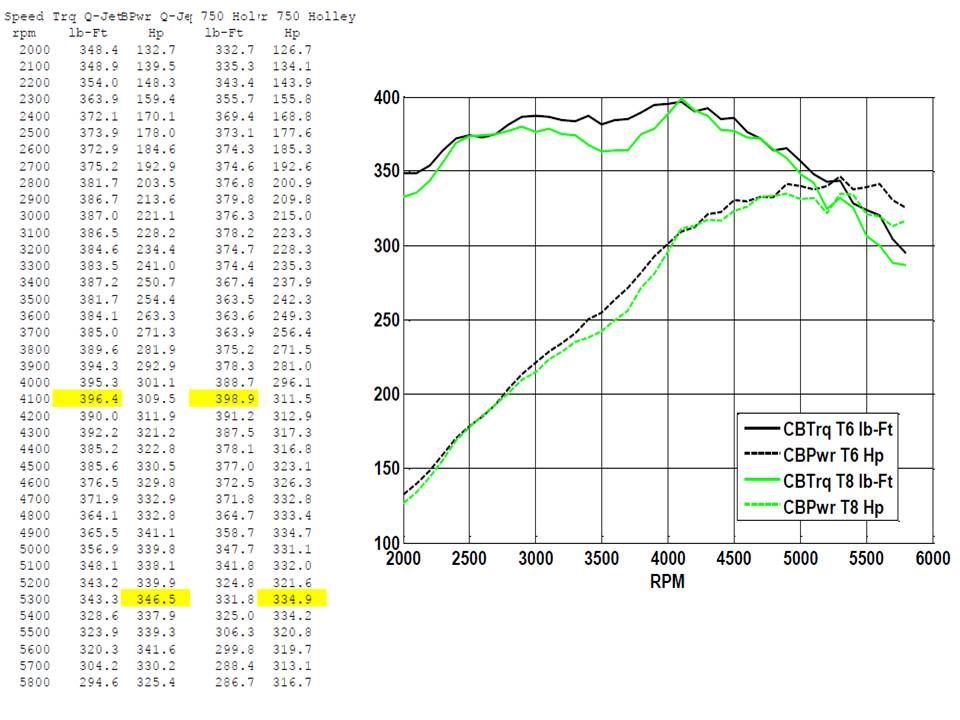

The Q-Jet bettered the Holley by 15 ft/lbs of torque on the bottom end, and pulled more than 20 ft/lbs at many data points, with a 10 to 20 horsepower gain over the Holley at many points through the range. The Holley produced a couple of peak numbers at limited points, but not enough to give it any advantage over the Q-Jet. The mass airflow numbers through the Holley were also lower than the airflow numbers through the Q-Jet at high rpm, and this can be seen by the drop-off in the Holley performance at the top of the curve. We even did one Holley run with me forcing the secondaries fully open for the top ½ of the rpm range, but this killed all the top-end numbers completely: The carb liked the “tall yellow” spring.

The numbers between the two carbs are fairly close, but if these 2 engines had been installed in 2 identical street cars, the Q-Jet car would have come across the finish line ahead of the Holley car by a significant margin.

This is not to say that either carb is “better.” But the fact is, that if you set these carbs up correctly, and know how to tune them, they can be made to run very well. There is no point in replacing a badly-tuned Q-Jet with a badly-tuned Holley or vice versa. A well-tuned Holley will run better than a badly-tuned Q-Jet, and this is what is usually the case in the “Holley is better than that crap Q-Jet” argument. If you have a good Q-Jet and know how to set it up, run it on your street car. If you don’t have a carb, or don’t know how to tune a Q-Jet, a Holley will run fine, but you better be able to tune it, too. Black lines are Q-Jet, green lines are Holley:

Lars

(http://www.corvetteactioncenter.com/forums/c3-technical-performance/130172-rochester-qj-set-up.html)

tracksnblades1 had some doubts about the Q-Jet’s abilities compared to Holley-based designs:

There has been a multitude of articles, writings and the sort published about these carbs. Ranging from excellent to BS. In closing I offer no defense on my comment of the Holleys perfromance. There are those still that believe these carbs are superior to FI also. Any carb can be modified to achieve almost ideal fuel curves and atomization that allows vaporization only to occur in the compression cylce. I have not read mister Lars Papers as refered to. I will. I will monitor his dyno tests as available. If convinced I may concur and reject the findings of the greats like Smokey, Barry Grant, NASCAR and the factory big three engineers who chose the Holley on their max efforts. AGE QUOD AGIS Do what you do, Well. Only the Best

I just finished up another dyno test of a mildly-built 400, and the results follow…

The engine was a stock-block 400 with stock factory cast iron heads. I got compression ratio up to 10.08:1 with flat-top pistons and the stock deck height. The bottom-end was kept stock with some good rod bolts, and the heads were given a good 3-angle valve job. The restrictive EGR intake was scrapped and an Edelbrock “Performer” intake was used to keep overall engine height near-stock so that there would be no hood interference problems. The owner wanted a very mild cam to maintain engine vacuum and power brakes, so a mild hydraulic roller was used. No other trick parts – the engine was pretty much a modest compression 400 with a mild roller in it.

The real purpose of the dyno run was to get good numbers for the owner and to get a good tune on the engine, but we also wanted to get a back-to-back comparison of a well-tuned Q-Jet to a properly set up Holley of similar size. Those results came in as expected…

For the first “out-of-the-box” dyno pull, the Q-Jet was used (17056263). This carb is factory jetted at 70/42/DB, which is awfully lean. I re-jetted the carb to 76/42/DB with a 3/8” float level and .640 secondary rod height. Other carb tuning and parameters were set up exactly as outlined in my Q-Jet Tuning Paper under the “Quickie Performance Setup” section.

After getting the timing optimized (the inefficient chambers in the iron heads took 41 degrees total timing for best power and torque without detonation – an increase from my initial setting of 37). We were using 91-octane pump gas with 10% ethanol – right out of the gas station down the street. Total timing was coming in before 2000 rpm – a very quick curve.

The 4 initial pulls we did on the engine showed a “dip” in the torque curve (with resulting “sag” in the power curve) between 3500 and 4000. This is right where the Q-Jet secondary airvalve is starting to open up, and the air/fuel numbers were showing a lean condition right at the tip-in of the secondaries. The stock “DB” secondary rods in the carb have the “short” power tips, which delay fuel enrichment. We installed a pair of Edelbrock “CL” rods which have about the same diameter (just a small tad richer), but they have the “long” power tips. Richening up the secondary tip-in point really flattened out the torque curve and made the power curve a near straight-line shot towards the top.

Once this had been sorted out and the Q-Jet was correctly tuned, I wanted to do the final run just to prove one of my pet-peeve points: Q-Jets are garbage, and any Holley will outperform a Q-Jet… blah, blah, blah… As I state in all my seminars and papers, a properly tuned Q-Jet will perform almost identical to a properly tuned Holley, except that the Q-Jet tends to produce better torque and throttle response in the low and mid range in a street driven vehicle than the Holley. Now that we had our Q-Jet pretty well dialed in, it was time for a switch to the Holley.

The Holley I selected was a 3310-1, which is a 750 vacuum secondary with the secondary metering block (not the cheap plate). The carb was set up and tuned to spec with 72 primary jets, 80 secondary, and the “tall yellow” secondary spring was selected to assure that the secondaries would actually open. Choke system was removed to give it all the airflow advantage it could get. Float levels, shooters, and all tuning parameters were all set up correctly and verified and “blessed” by noted NASCAR engine builder Steve Yacki (who was also our dyno operator this day). The Holley was given 2 pulls on the dyno, and we verified that the air/fuel ratio on the Holley was virtually identical to the Q-Jet: The A/F numbers matched exactly at many data points, and were never different by more than 0.5:1 at any time through the entire rpm range – the 2 carbs were metering air and fuel at exactly the same ratio, so there was no “fudging” any numbers on these pulls.

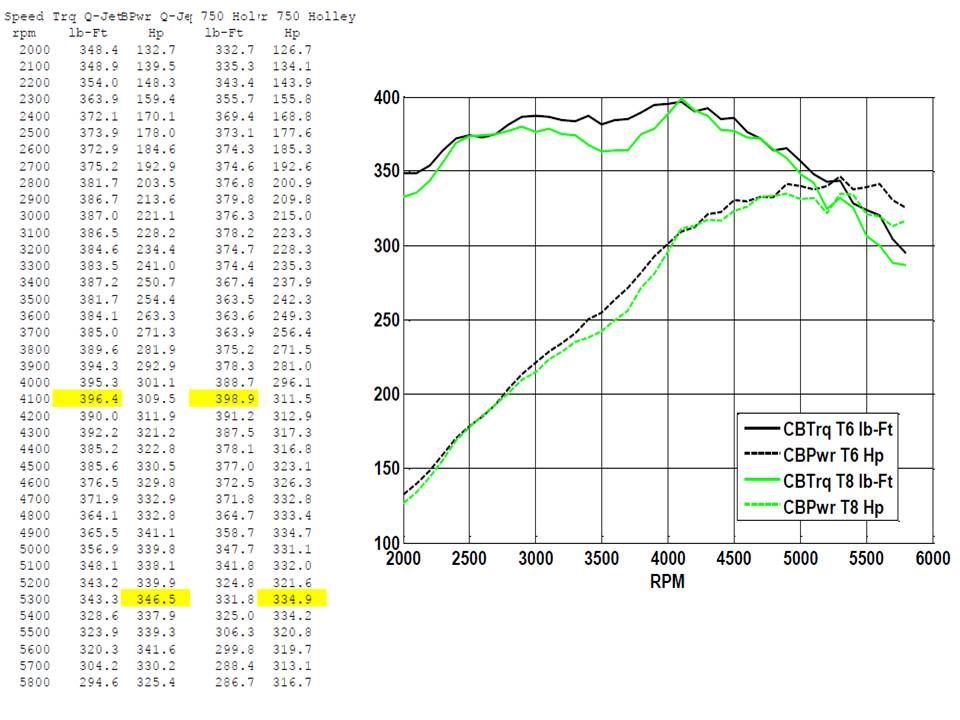

The Q-Jet bettered the Holley by 15 ft/lbs of torque on the bottom end, and pulled more than 20 ft/lbs at many data points, with a 10 to 20 horsepower gain over the Holley at many points through the range. The Holley produced a couple of peak numbers at limited points, but not enough to give it any advantage over the Q-Jet. The mass airflow numbers through the Holley were also lower than the airflow numbers through the Q-Jet at high rpm, and this can be seen by the drop-off in the Holley performance at the top of the curve. We even did one Holley run with me forcing the secondaries fully open for the top ½ of the rpm range, but this killed all the top-end numbers completely: The carb liked the “tall yellow” spring.

The numbers between the two carbs are fairly close, but if these 2 engines had been installed in 2 identical street cars, the Q-Jet car would have come across the finish line ahead of the Holley car by a significant margin.

This is not to say that either carb is “better.” But the fact is, that if you set these carbs up correctly, and know how to tune them, they can be made to run very well. There is no point in replacing a badly-tuned Q-Jet with a badly-tuned Holley or vice versa. A well-tuned Holley will run better than a badly-tuned Q-Jet, and this is what is usually the case in the “Holley is better than that crap Q-Jet” argument. If you have a good Q-Jet and know how to set it up, run it on your street car. If you don’t have a carb, or don’t know how to tune a Q-Jet, a Holley will run fine, but you better be able to tune it, too. Black lines are Q-Jet, green lines are Holley:

Lars