good job .let us know what else you do to make it run right.

Update - Playing with some of the basics right now. (Whew - long post eh?)

Timing finally tweaked after wasting a day looking for the EST connection (the "tan wire" actually has a black stripe on it). Found the timing at ~ 20 BTDC so I adjusted to ~ 10.

Checked FP - at 15 lbs.

Did the feeler gauge test on the throttle plates for a rough sync - they were at a perfect .0015. Assume the guys at the shop did that - maybe DCS set "em they bored "em to 2". Manometer alignment put off for some future time...

Next checked IAC's. They were loose I could untighted "em with my hand. Pulled "em, sprayed the nose and the empty TBI IAC port w/carb clnr. Made sure they were not extended further than 1 1/8", fabbed a washer and reassembled at 13 lbs torque.

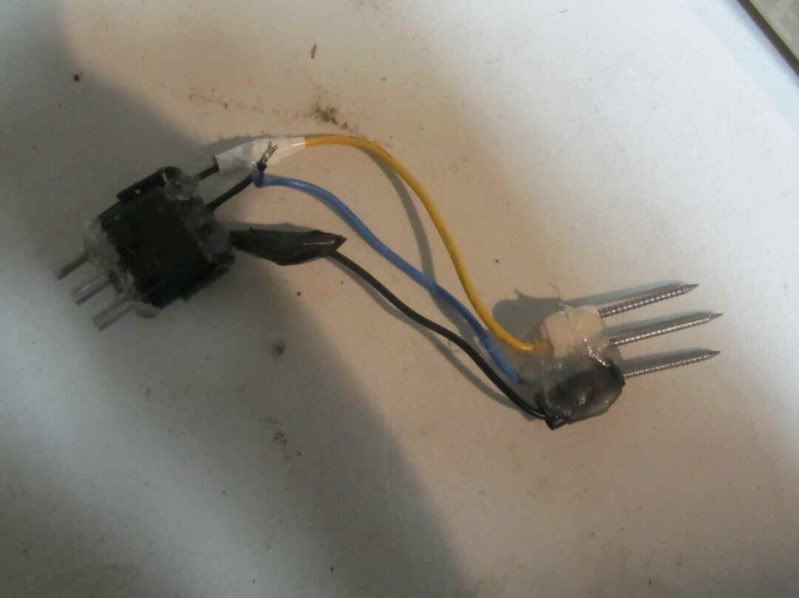

Then looked at the TPS, jeez it only had one screw - spent the next two days trying to find a screw that would fit and ended up buying a new TPS. Got an OK buy from Rock Auto <$30 delivered. Fabbed a test connection see pic (hot glue, spine nails, and a hacked O2S connector) and set it at

.53 volts.

OK time for a test drive. Results - running a little better, idle down from ~1,100 to a very jumpy 525 to 620 and it's killing at stop in gear about 60% of the time. Also feels flat, engine seems to labor and not know what to do with a quick punch on the pedal. Back home pop the hood - forgot to reconnect the EST - dumb schitck!

Back on the road - no more killing, idles a little rough but much better ~575 to ~ 625+. Handling the pedal punch just a bit better but still seems to labor way too much - it just ain't running efficiently yet. I guess have to do some VE learns - wish I knew how. Also told I need to watch the AFR closely. Don't even know if I can do that with the set up I have. Will keep reading -

If you'd like to jump in and suggest some next things to do – great! (BTW soon ... not a lot of nice test drive days left up here in the arctic. So I'll be shutting down the tuning and working the interior shortly).

Thanks.

BTW this is what I have - 355, 9.72:1, Renegade (of course), CAM (224/224 .450/.460 @.05 114 LSA), TBI's to 2" by DCS, Hammed 8746 w/EBL, True Duals, Hi Flow Muflrs

otfl

otfl