First I’d like to say I’m not an EXPERT at welding but have done quite a bit over the last 35 years.

Now to answer some basic questions. Here is some info from a different site you might want to know!

I'll try to explain some of the basics for you as best I can.

http://www.alpharubicon.com/elect/tigbasic1.htm

TIG - (Tungsten Inert Gas Welding)

Basically resembles oxy-acetylene welding (torch) but you use a controlled electric arc as the flame/head source and feed in the weld wire or rod separate from the arc.

This process is the toughest to learn. The electrode is composed of Tungsten and current flows through it. The current is controlled by a foot pedal, hand switch or fixed current on the machine itself.

I am learning TIG using a foot pedal The more you press down on the pedal, the more amps you get. Once you get enough current flowing to get an appropriate sized weld pool, you start dabbing filler metal into the puddle as you move the electrode further down the work piece. TIG allows you a great amount of control because you regulate how much current the electrode gets and how much filler metal the weld pool gets. This process is very slow compared to the other types welding.

MIG - (Metal Inert Gas)

MIG is basically a wire that has current running thru it, that is fed constantly into the weld area. It melts both the metal and itself as its consumed/melted by the arc.

http://www.autobody101.com/articles/article.php?title=Mig+Welding

MIG is the easiest type of welding. A feed gun is used to feed metal wire from a spool into the weld pool. Current and wire feed is usually switched on and off by means of a trigger on the gun. A dial on the MIG machine usually controls the amps and you cannot adjust current while welding. With some machines you are able to use a foot pedal to control Amps while welding.

Arc Welding

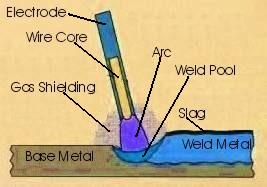

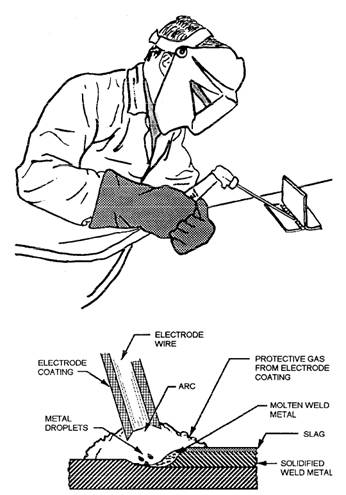

These are the cheap buzz box welders we usually start with. They use an arc thru the weld rod somewhat similar to MIG but without the gas shielding. They have flux on the rods that produce shielding as it burns, to help the weld quality.

Arc welding is mostly used in industrial applications. An electrode is used to strike an arc, then the electrode melts away to deposit metal into the weld pool. The electrode is coated with a variety of different materials, which are used to help keep the weld pool from being contaminated.

TIG and non-flux-cored MIG both use a variety of different shielding gases to help keep the weld pool from being contaminated depending on what metal is being welding.

http://www.stockcarracing.com/techarticles/82101/

http://www.ytmag.com/articles/artint153.htm

http://www.popularmechanics.com/home_improvement/tools/2001/3/welding_basics/

the most comon mistake I see is guys buying a cheap underpowered welder, the wrong type of welder or not understanding how to use the welder they buy, many colleges and trade schools have classes on welding open cheaply to the public, and are well worth the time and expence to attend them ....and you damn sure need a self darkening helmet YOUR EYESIGHT IS WORTH FAR MORE THAN THE $200 they cost on EBAY