If this is thought thru, it fails to make sense.

That EGR should have sufficient vac control pressure to operate when necessary BECAUSE the EGR generally only opens when the engine is under a load or bogs and THAT is when combustion temps shoot upward...the EGR is/was never intended to be

only an emissions control device. It has benefits to emissions but its design purpose was to cool combustion to help prevent meltdowns with leaner/meaner engines as engine mngt technology evolved in the early 70s.

Is this EGR being expected to correct some other underlying problem? poor fuel control? air leak? worn injectors? worn valves/cam? Something is not right. If it were simply an issue with the neg/pressure EGR valve them there would be 100's of thousands of 80s, 90's and even 2000 yr model cars failing the test faster then they could line up.

Another thing..the "neg" pressure EGR is NOT operated/controlled by the exhaust. That "Negative" is in reality vacuum...

(neg pressure is vacuum)meaning it is vac operated. The big difference in the different type of EGR operations is the bleed off by way of a pin hole with a little ball/check/spring that allows exhaust to equalize and bleed off the vac thats holding the valve open. Thats how its able to close since the vac may remain and until there is positive pressure introduced. Like Hib said, stuffing a rag in the tail pipe forced each stroke to hold more used or burnt exhaust gas into the next cycle so the Nox went down briefly...same thing as the EGR opening and sending exhaust gas into the cylinder. Since we now know that the addition of exhaust does work in the right direction we need to focus on why that is not happening thru the design.

EGR operation is a balancing act of vac opposed to pressure...neg vs pos.

BTW, we need to clarify that the EGR is often described as "adding cold or burnt exhaust gas to the combustion process to cool it down"..... The word 'cold' is relative . Exhaust gas that is 1400 degrees IS

colder than combustion thats up to 3000 degrees.

We want the EGR to open just enough to drop the combustion temps, which reduce the high oxides of nitrogen. Toxic and corrosive they are the by product of high combustion temps. So, when we lean out the fuel/air to lower the hydrocarbons, we raise the combustion temp and Nox. In order to lower THAT, we have to lower the temp of combustion without raising the hydrocarbons. We keep hydrocarbons DOWN by a good, high temp clean burn that completely burns all the fuel. The cat does the rest with an added shot of o2 to get that last little hydrocarbon molecule....so what does not burn is converted to harmless h20 vapor.

So, its a constant balance that we seek in the exhaust thats in need of constant adjustment because of the varying demands on the engine.

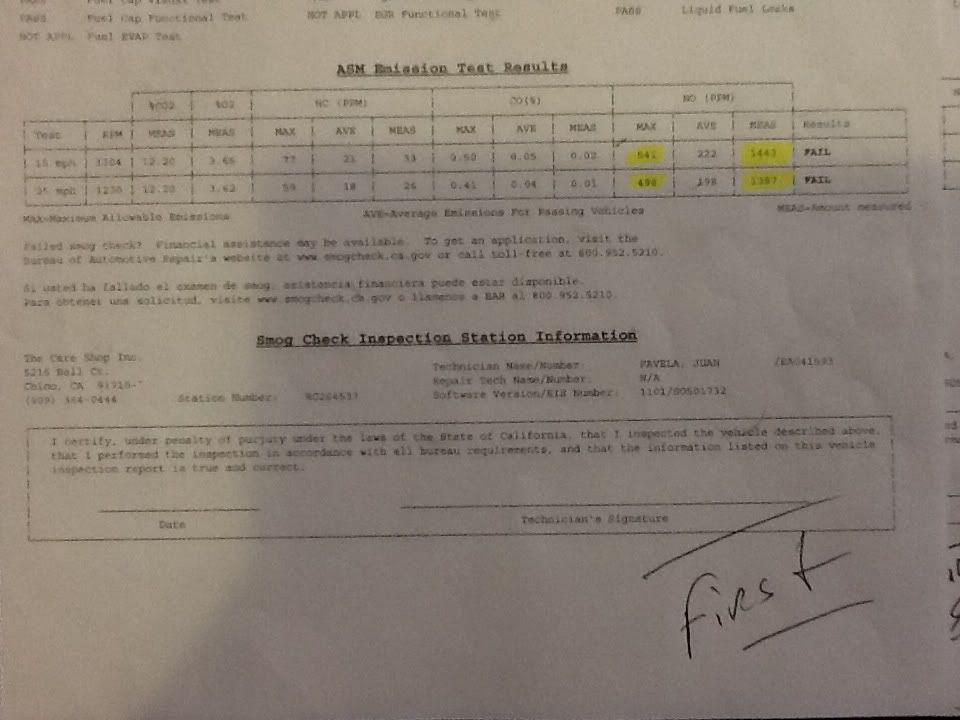

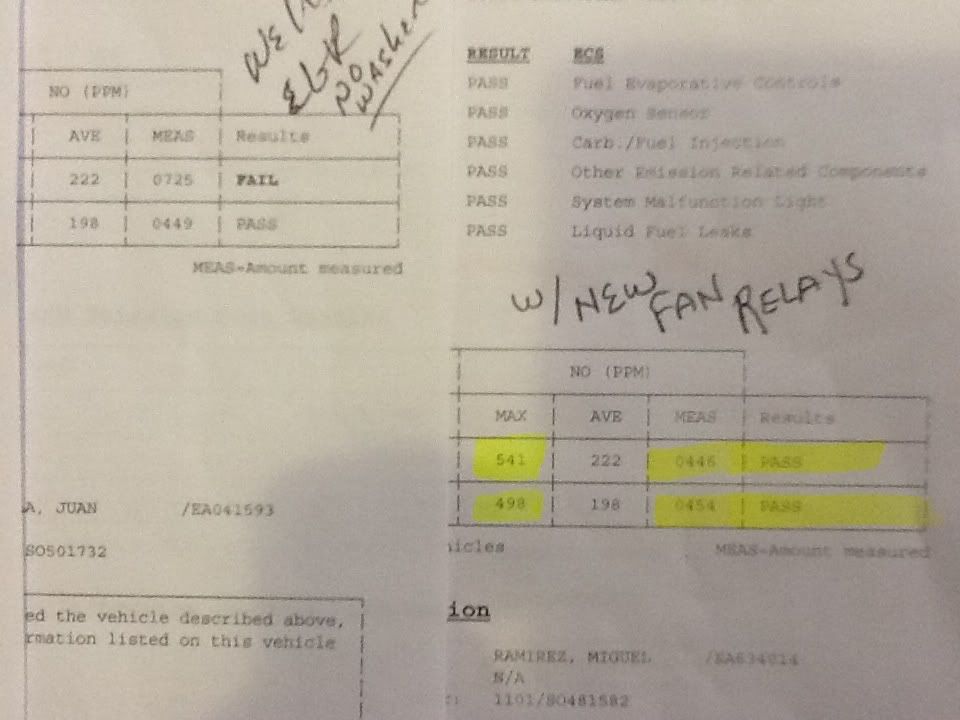

IF you Nox are wayyyy high, then manually operating the EGR would be an appropiate test. IF that helped, THEN move to discover whats preventing that from happening automatically....poor vac control, bad EGR valve itself, or restricted passage for the exhaust gas to flow and enter? Was the EGR tube ever replaced and welded in? could the passage be partially blocked? Again, if the egr lowers the Nox when operated manually with a vac pump..or even sucking on the hose, your engine may not be supplying the necessary vac to make it work well.

Take each fact and take it thru the many possibilities to the logical conclusion of each.

Is the engine performing well besides the poor emissions? low HC? No oil burning? I personally think that is wayy over-thinking the problem, and after many yrs of working with this type of thing,

I find Occams Razor to be most true and useful.

http://pespmc1.vub.ac.be/OCCAMRAZ.html

I hope that you get it figured out by tweeking the EGR or whatever has to be done, but after reading all this and watching from a distance I have to believe there is something simple thats causing the high numbers other than an EGR that was designed for that particular engine

Good Luck

ad

ad