Paul Higg

Well-known member

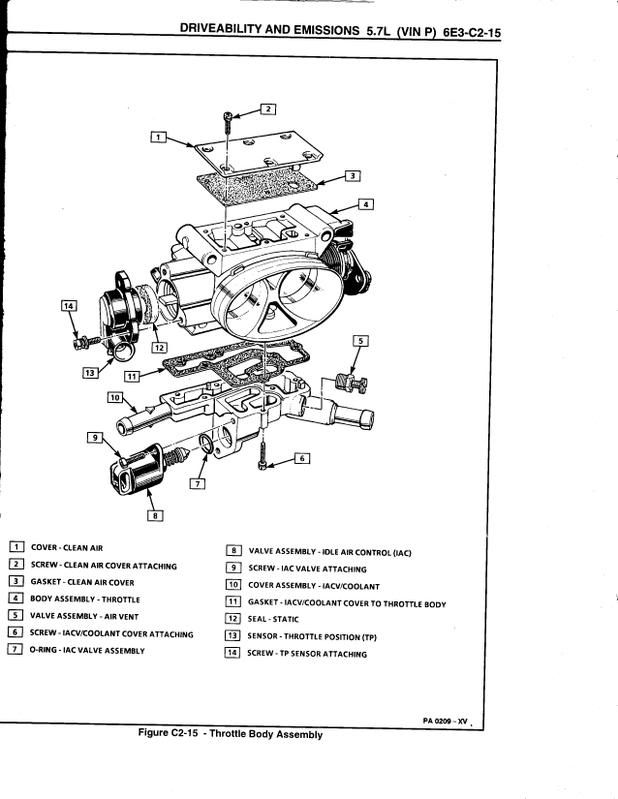

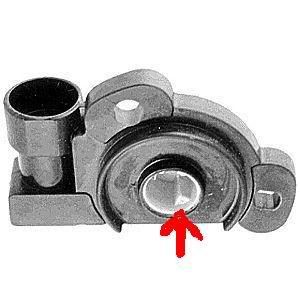

Is it even possible to reinstall the throttle position sensor?

I removed the throttle body for cleaning and stupidly removed the sensor. It seems as if it has some sort of spring pre-load in it. When I reinstall it no matter what position the butterfly flaps are in it does not "catch" on the TPS's little "ears" in it. This is freaking me out.

Also, I just drained a little fluid from the radiator to remove the TB for cleaning and when I started refilling it I noticed a small drip under the car directly under the TB but there are no leaks under it. I used new gaskets and I can see it is dry, the whole area around the TB is dry. I think it might be the water pump. But it is so cramped in there that even with a mirror I cannot see. All I see is a green drip from a piece of metal under the car. I crawled under there with a light and mirror and cannot see where it is leaking. I cannot see anything from the top because it is so cramped. This is really starting to get me down.

Paul

94 LT1

I removed the throttle body for cleaning and stupidly removed the sensor. It seems as if it has some sort of spring pre-load in it. When I reinstall it no matter what position the butterfly flaps are in it does not "catch" on the TPS's little "ears" in it. This is freaking me out.

Also, I just drained a little fluid from the radiator to remove the TB for cleaning and when I started refilling it I noticed a small drip under the car directly under the TB but there are no leaks under it. I used new gaskets and I can see it is dry, the whole area around the TB is dry. I think it might be the water pump. But it is so cramped in there that even with a mirror I cannot see. All I see is a green drip from a piece of metal under the car. I crawled under there with a light and mirror and cannot see where it is leaking. I cannot see anything from the top because it is so cramped. This is really starting to get me down.

Paul

94 LT1