There almost has to be some sort of contact in the heads if the rockers are free to their full travel and the springs are not binding or bottoming out too early.

Is it possible that the cam with the 1.6 rocker is TOO much for the heads? deck height?

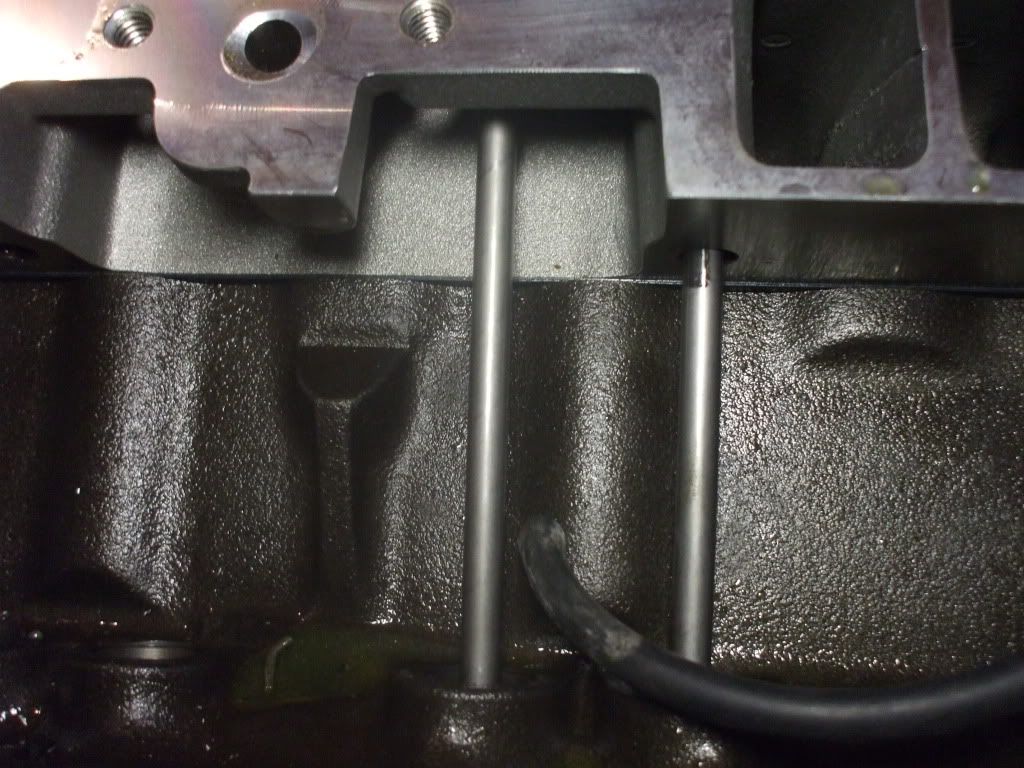

Is the springs compressed length too short for the cam lift with the 1.6 rocker? If the springs compressed length is less than that, the difference will be taken out in the weakest part, the pushrods. It may be as little as a couple thousanths since metal does not compress, it will distort. Once the lifter is bottomed out and the plunger cannot absorb anymore, the stress goes directly to the hard parts. Lifters are like shocks in this way.

Is it possible that the cam is not for a roller motor? or one of the other valve-train parts? That matters a bunch.

Its not a valve hitting a piston...I don;t think, unless the cam was opening the intake wayyyyy too early before the piston was beyond TDC exhaust stroke. The intake should begin to open just as the crank pulls the piston down, depending on the cam profile.

If these pushrods are still bending, only on intake, whats the common denominator? the 1.6 rocker? and the head deck height and the cam.