Paul Higg

Well-known member

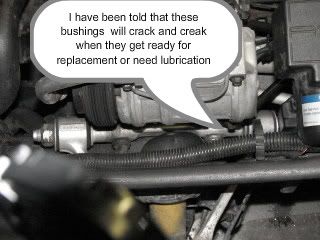

Junk, I tried your suggestion today about the sway bar and the moly grease and it is still making the same exact noise. I noticed on my test drive tonight that when I go over a speed bump at say 2 or 3 MPH, no noise, but if I go over it at 8 MPH CREAK!!! And it sounds mostly like it is coming from the front end.

Any other suggestions as I am about to put this car to sleep, maybe a couple of bullets, wait, no, how about this, THERMITE!!

Seriously, this is P*****G me OFF!

Could it be some other bushings? Front leaf spring bushings? It SOUNDS like it is rubber and it also SOUNDS like an old wooden sailing ship with the boards creaking BIG time.

Paul :W ;help

:W ;help  :bash

:bash mad

mad mad

mad mad

mad ad

ad

Any other suggestions as I am about to put this car to sleep, maybe a couple of bullets, wait, no, how about this, THERMITE!!

Seriously, this is P*****G me OFF!

Could it be some other bushings? Front leaf spring bushings? It SOUNDS like it is rubber and it also SOUNDS like an old wooden sailing ship with the boards creaking BIG time.

Paul

:W ;help

:W ;help  :bash

:bash ad

ad

otfl

otfl