- Thread starter

- #41

Bob Heine

Well-known member

Bill,Sounds like you have it on the run BobWish I had half your energy, seems as I am going to have to retire to get anything done here lately, just get a good start and time to go back to work :ugh, retirement is on my horizon though

Bill

Many of my friends refuse to retire -- what would they do if they didn't work. A lot of people suffer stress-related disorders when they retire but I'm not one of them. Just make sure you have a project ready to go when you retire. At the beginning, treat it like a job. I didn't disappear into the garage for 8-hours a day when I first retired. Seeing me wandering around 'her' space during the workday was too much for her.

I retired at 50 when IBM offered me a buyout. Wife sent me back to work after 7 months (I think the set of knives I ordered from QVC triggered that). Four years commuting between Florida and Washington DC every other week changed her mind but she made me promise to spend my time in the garage and not invading her space.

We found our dream home 3 bedroom, 2 bath with pool and large yard in a downtown neighborhood (I visit her 1700 square feet and she checks to be sure I'm OK in my 900 square feet). I had to repair some termite damage in the garage so insulation and AC became part of the repair. Upgraded the 3 garage doors to meet hurricane code and insulated them at the same time. The garage is equipped with a few amenities, like a surround sound system, deep sink, refrigerator, freezer, ice maker, microwave, coffee bar and a new hybrid water heater. In addition to the $500 energy credit, I saved $300 by installing the water heater myself. The savings justified replacing the old 27" CRT TV with a 32" LCD high def flat screen. Added a blue-ray player with wireless internet so I can watch basic cable TV, blue-ray disks or Netflix. Most of the time I just listen to CDs -- a 400 CD changer is part of the sound system. Wife lets me use the second bathroom (as long as I keep it clean).

One of the bedrooms is my former office so four computers are networked in there and the laptop resides in the master bedroom (hooked up to the 'big' screen to make it easier to keep my wife supplied with horror movies on Netflix).

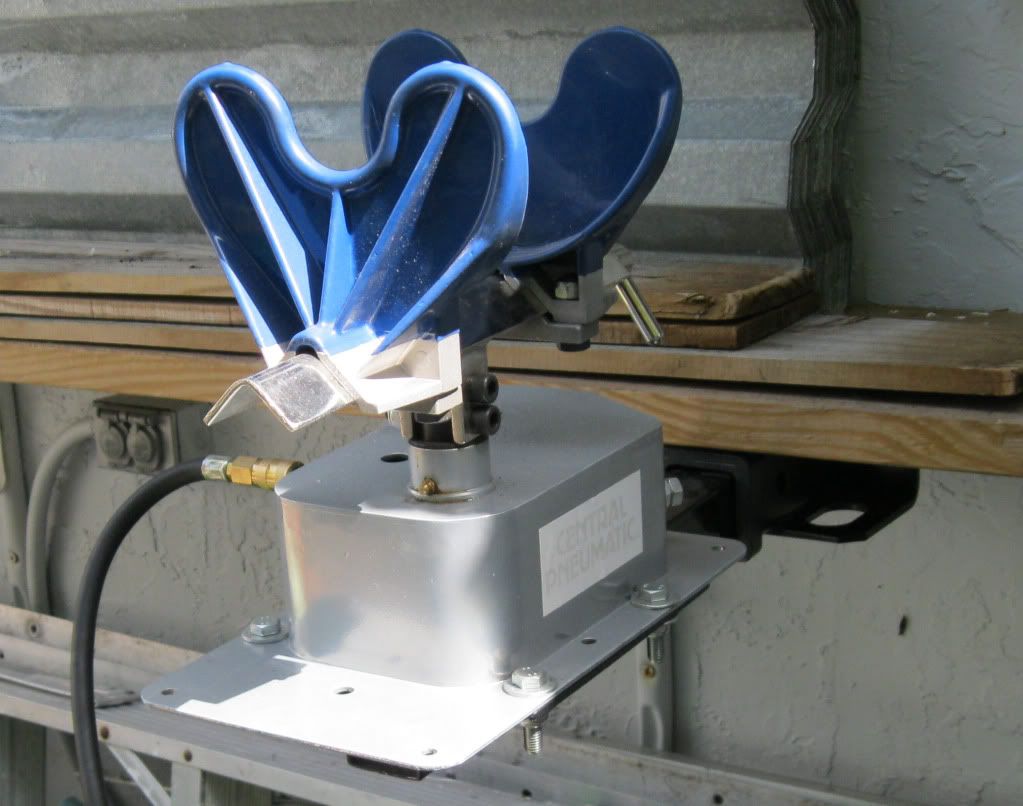

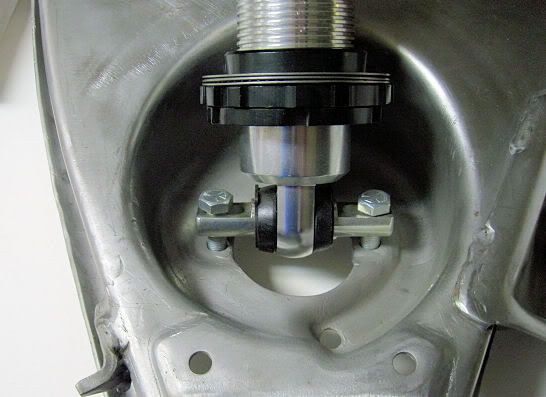

enabled me to get one of these done in less than three hours. Let's see, measure four times, double check, measure again, make one cut – repeat process for each additional cut and then go to work with grinders, files and sanding wheels. Measure and mark holes, drill a pilot hole and then use a step drill to enlarge for 3/8" bolt -- followed by a little more filing.

enabled me to get one of these done in less than three hours. Let's see, measure four times, double check, measure again, make one cut – repeat process for each additional cut and then go to work with grinders, files and sanding wheels. Measure and mark holes, drill a pilot hole and then use a step drill to enlarge for 3/8" bolt -- followed by a little more filing.

Because of work or being drained all week because of it I have not even had the C-5 on the road yet this year and that is a :crying shame.

Because of work or being drained all week because of it I have not even had the C-5 on the road yet this year and that is a :crying shame.