Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help! Module 1 C41 Module 4 Err Module 9 H72

- Thread starter 1992BearC4

- Start date

- Thread starter

- #62

1992BearC4

Well-known member

Yes that is the code on top of the rectangular chip on the assembly that is what came back with the ecm when it was rebuilt. Maybe they screwed something up ? I will take a picture after work on post to make sure I'm reading the right stuff.

E

ecss

Guest

Yes that is the code on top of the rectangular chip on the assembly that is what came back with the ecm when it was rebuilt. Maybe they screwed something up ? I will take a picture after work on post to make sure I'm reading the right stuff.

Usually when a ECM is sent in for repair, they tell you to remove the Calpak.

The Broadcast Code is usually imprinted on a sticker on the Eprom or somewhere in that area.

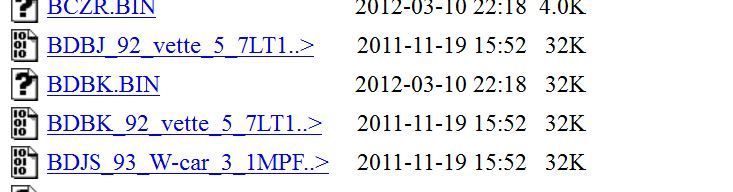

The Broadcast Code BDJS says it's used on a 16149396 ECM

The 92 Corvette uses a 16159278 ECM

Here's a PDF that shows the BCC's and what computer they are used on.

Click on the URL below.

http://www.scotthansen.net/BCCLookup.pdf

Example showing the 4 character BCC

Last edited by a moderator:

- Thread starter

- #64

1992BearC4

Well-known member

Usually when a ECM is sent in for repair, they tell you to remove the Calpak.

The Broadcase Code is usually imprinted on a sticker on the Eprom or somewhere in that area.

The Broadcast Code BDJS says it's used on a 16149396 ECM

The 92 Corvette uses a 16159278 ECM

Here's a PDF that shows the BCC's and what computer they are used on.

Click on the URL below.

http://www.scotthansen.net/BCCLookup.pdf

Ya that's the same area that I read bdjs same sticker also

Example showing the 4 character BCC

Ya that looks exactly like what I got those letters from

- Thread starter

- #65

1992BearC4

Well-known member

E

ecss

Guest

Here are the pictures of the PROM

The ECM #'s on the ECM that run the car 16159278 ECUEA183

The ECM#'s on the ECM that don't work are 16138461

The 16138461 ECM is for a V6 engine. The cal pak/memcal assembly for that ECM is the BDJS.

The 16159278 is the correct Corvette ECM for a 92 or 93.

Now you need to get the correct cal pak/memcal assembly for a 92 Corvette with Eprom programmed with

the correct transmission (auto or manual trans) and rear axle ratio for your car. The rear axle ratio

should be on the factory options sticker either under the center console door or under one of the rear

storage hatch doors. (like GM3=3.45, GU2=2.73, G44=3.07 etc...)

At the minimum you need the correct calibration pak and the Eprom can be reprogrammed.

As far as I know the calibration pak contains the circuitry to allow the car to run with a partial ECM failure.

Last edited by a moderator:

- Thread starter

- #67

1992BearC4

Well-known member

Okay great !! I found an EPROM/CALPAK and will order wont be here for about 7-10 days then will post back with the results and go from there, can't thank you enough for all the help !

- Thread starter

- #68

1992BearC4

Well-known member

Well got it back together with the correct CalPack/PROM from Zip Corvette. Now it starts and kinda runs but I can now read codes and Data from my scanner for the first time in 2 1/2 years !!. It wont idle now and feels like a misfire but when you give her some gas it smooths out ? I replaced the IAC and found the old one to be seized and really carboned up and also the ECT sensor was reading 30 dergrees on the high side so I replaced that also. Took it for a drive and other than the idle issue it drives pretty good off idle ? Not sure where to go from here but at least it runs with no more waring lights and SYS messages !! Thinking maybe old gas and possible dirty fuel injectors and or Fuel Filter ?

E

ecss

Guest

Well got it back together with the correct CalPack/PROM from Zip Corvette. Now it starts and kinda runs but I can now read codes and Data from my scanner for the first time in 2 1/2 years !!. It wont idle now and feels like a misfire but when you give her some gas it smooths out ? I replaced the IAC and found the old one to be seized and really carboned up and also the ECT sensor was reading 30 dergrees on the high side so I replaced that also. Took it for a drive and other than the idle issue it drives pretty good off idle ? Not sure where to go from here but at least it runs with no more waring lights and SYS messages !! Thinking maybe old gas and possible dirty fuel injectors and or Fuel Filter ?

I would remove the IAC and spray throttle body cleaner in the IAC bore to clean out the idle passages.

Usually a car that sits that long will have rust in the tank. The fuel pump assembly corrodes and fine

particles of rust start floating around. Pull the pump assembly and siphon the gas out. Use a sponge to get any remaining gas out. Wipe the inside of the tank down with a rag. Wire wheel any rust off of the fuel pump assembly. Be careful and do not bend the float arm.

Note the position of the original fuel pump sock. Install a new fuel pump sock in the same orientation and replace the fuel filter on the passenger side frame rail behind the front tire.

Verify the fuel pressure with a gage attached to the fuel rail. Should be over 40 psi. and when the ignition key is turned off the fuel pressure should hold and slowly bleed off after 10 minutes.

Start the car in a dark area and verify there is no arching from the plug wires.

You say there is a slight miss?

Since you have a scanner look at the short and long term fuel trims.

Both should be close to 128.

You have two o2 sensors so you can compare the values. Bank 1 is the driver side and Bank 2 is the

passenger side o2 sensor.

If you have a clamp on timing light, attach it to each spark plug wire and verify the timing light flashes

for each plug wire.

- Thread starter

- #70

1992BearC4

Well-known member

Will do the throttle body cleaning in the am and the fuel system clean and pressure test. Great idea about the timing light never thought of that. I will print out a data sheet from my scanner and post it when I get off work tommrow. If I remember right the LTFT were both around 128 but I could be wrong but the data print will tell. Thanks again so much for all the help as it finally is coming back to life again.

Hib Halverson

Technical Writer for Internet & Print Media

Wow!

What an interesting solution.

Nice work "ecss"!

What an interesting solution.

Nice work "ecss"!

- Thread starter

- #72

1992BearC4

Well-known member

This is Data Log from After the Fuel Pump Sock Replacement/Fuel Filter and Fuel Treatment. I have not got to the throttle body cleaning yet, and gonna do the timing light test on all the plug wires tomrrow maybe this will shed some light on the remaining issues. Thanks ! On question what does it mean Inj 1 and Inj 2 Fault ?

Last edited:

E

ecss

Guest

Engine was only running for 37 seconds.

Need to see if the computer will go into closed loop.

The ECM will then use the O2 sensors to determine the fuel trims.

O2 sensors need to get over 600F before there is a usable signal.

If you were to graph the 02 signals you should eventually see a sine wave when

the o2's are usable.

1) RPM's show 1783 is this with you pressing the gas pedal?

2) Left and Right integrator will be a 128 because you're not in closed loop.

3) Injector fault YES indicates the ECM does not detect voltage at the injector driver.

After the ignition has been OFF for ten seconds, turn the ignition to the ON position. Injector faults

should now indicate NO. Not sure what this parameter indicates. :eyerole

4) If you turn the ignition ON engine not running does the scanner show the Throttle Position Sensor

voltage go from .68 to around 4.8 volts when you press on the gas pedal?

5) If the scanner shows % of throttle position does it show 0% to 100% when the gas pedal

is full depressed?

6) When the engine is first started the air pump located in front of the driver side front tire turns on and injects

air into the exhaust ports. Not sure how long it stays on but the parameter Air Control Solenoid should

eventually go to divert. In your scan sheet it shows Port which indicates it's injecting air into the exhaust which is normal but eventually it should show divert.

7) Have you actually verify fuel pressure with a gauge?

Go ahead and clean the throttle body and verify you're running on eight cylinders.

Run the engine until it goes into closed loop and see what the parameters show.

Need to see if the computer will go into closed loop.

The ECM will then use the O2 sensors to determine the fuel trims.

O2 sensors need to get over 600F before there is a usable signal.

If you were to graph the 02 signals you should eventually see a sine wave when

the o2's are usable.

1) RPM's show 1783 is this with you pressing the gas pedal?

2) Left and Right integrator will be a 128 because you're not in closed loop.

3) Injector fault YES indicates the ECM does not detect voltage at the injector driver.

After the ignition has been OFF for ten seconds, turn the ignition to the ON position. Injector faults

should now indicate NO. Not sure what this parameter indicates. :eyerole

4) If you turn the ignition ON engine not running does the scanner show the Throttle Position Sensor

voltage go from .68 to around 4.8 volts when you press on the gas pedal?

5) If the scanner shows % of throttle position does it show 0% to 100% when the gas pedal

is full depressed?

6) When the engine is first started the air pump located in front of the driver side front tire turns on and injects

air into the exhaust ports. Not sure how long it stays on but the parameter Air Control Solenoid should

eventually go to divert. In your scan sheet it shows Port which indicates it's injecting air into the exhaust which is normal but eventually it should show divert.

7) Have you actually verify fuel pressure with a gauge?

Go ahead and clean the throttle body and verify you're running on eight cylinders.

Run the engine until it goes into closed loop and see what the parameters show.

- Thread starter

- #74

1992BearC4

Well-known member

Engine was only running for 37 seconds.

Need to see if the computer will go into closed loop.

The ECM will then use the O2 sensors to determine the fuel trims.

O2 sensors need to get over 600F before there is a usable signal.

If you were to graph the 02 signals you should eventually see a sine wave when

the o2's are usable.

1) RPM's show 1783 is this with you pressing the gas pedal?

2) Left and Right integrator will be a 128 because you're not in closed loop.

3) Injector fault YES indicates the ECM does not detect voltage at the injector driver.

After the ignition has been OFF for ten seconds, turn the ignition to the ON position. Injector faults

should now indicate NO. Not sure what this parameter indicates. :eyerole

4) If you turn the ignition ON engine not running does the scanner show the Throttle Position Sensor

voltage go from .68 to around 4.8 volts when you press on the gas pedal?

5) If the scanner shows % of throttle position does it show 0% to 100% when the gas pedal

is full depressed?

6) When the engine is first started the air pump located in front of the driver side front tire turns on and injects

air into the exhaust ports. Not sure how long it stays on but the parameter Air Control Solenoid should

eventually go to divert. In your scan sheet it shows Port which indicates it's injecting air into the exhaust which is normal but eventually it should show divert.

7) Have you actually verify fuel pressure with a gauge?

Go ahead and clean the throttle body and verify you're running on eight cylinders.

Run the engine until it goes into closed loop and see what the parameters show.

Ok Will do that and post back tommrrow night. The TPS from what I remember goes from around .62 volts to 2.80 volts with the pedal depressed all the way down. Fuel Pressure 42 PSI on the rail and I didn't see much bleed down until about 10 mins after. One last note it is very rich on initial start-up (raw gas)

Last edited:

E

ecss

Guest

The TPS from what I remember goes from around .62 volts to 2.80 volts with the pedal depressed all the way down.

You need to verify that. The reference voltage is 5 volts so it should be close to that at wide open throttle.

Fuel Pressure 42 PSI on the rail and I didn't see much bleed down until about 10 mins after. One last note it is very rich on initial start-up (raw gas)

Pull the hose off of the fuel pressure regulator and verify there is no gas in the vacuum line.

Also remove the fuel injector connector from each injector and measure the resistance across each

fuel injector coil winding. I think they should be around 12.5 ohms. You're looking for all of the resistances to be the same.

You need to verify that. The reference voltage is 5 volts so it should be close to that at wide open throttle.

Fuel Pressure 42 PSI on the rail and I didn't see much bleed down until about 10 mins after. One last note it is very rich on initial start-up (raw gas)

Pull the hose off of the fuel pressure regulator and verify there is no gas in the vacuum line.

Also remove the fuel injector connector from each injector and measure the resistance across each

fuel injector coil winding. I think they should be around 12.5 ohms. You're looking for all of the resistances to be the same.

- Thread starter

- #76

1992BearC4

Well-known member

The TPS from what I remember goes from around .62 volts to 2.80 volts with the pedal depressed all the way down.

You need to verify that. The reference voltage is 5 volts so it should be close to that at wide open throttle.

Fuel Pressure 42 PSI on the rail and I didn't see much bleed down until about 10 mins after. One last note it is very rich on initial start-up (raw gas)

Pull the hose off of the fuel pressure regulator and verify there is no gas in the vacuum line.

Also remove the fuel injector connector from each injector and measure the resistance across each

fuel injector coil winding. I think they should be around 12.5 ohms. You're looking for all of the resistances to be the same.

Does it matter for the resistance test on a Hot or Cold Engine ?

E

ecss

Guest

Does it matter for the resistance test on a Hot or Cold Engine ?

The LT1 injectors are so easy to check you could check them when cold and hot to eliminate a coil resistance

problem. That doesn't eliminate them if they are clogged or have a poor spray pattern. You can do that by lifting up the fuel rail and cranking the engine. Of course place cups under the injectors to catch the fuel.

- Thread starter

- #78

1992BearC4

Well-known member

The LT1 injectors are so easy to check you could check them when cold and hot to eliminate a coil resistance

problem. That doesn't eliminate them if they are clogged or have a poor spray pattern. You can do that by lifting up the fuel rail and cranking the engine. Of course place cups under the injectors to catch the fuel.

Yes when it first starts it runs very rich almost like RAW FUEL smell out exhaust. I had it running trying to go into closed loop and started to smell something getting hot ! and I used and infrared gun on the Catalytic Converters and they read almost 800 degree's so I shut it down ? If I keep my foot on the throttle a little it will stay running but will not IDLE even after cleaning the IAC passages and putting a new IAC and harness pigtail on it ? THANKS

I will Ohm out the injectors in the AM and post tommrow and the TPS voltages.

Last edited:

- Thread starter

- #79

1992BearC4

Well-known member

Ohm results on the Injectors are 12.1 the lowest 12.3 the highest on a cold engine.

The TPS voltage goes to 2.90 with foot to the floor and show TPS% at 68 with foot to the floor.

The TPS voltage goes to 2.90 with foot to the floor and show TPS% at 68 with foot to the floor.

- Thread starter

- #80

1992BearC4

Well-known member

Ok so I found the ASR Adjustment and did that and then rechecked the TPS Voltage and Percentage and they are now at .68 volts/0 % closed throttle and 4.45 volts/99% wide open throttle. I hooked a timing light to each plug wire and it flashes great until the stumble starts. When it tries to idle the timing light gets dimmer and then right when it wants to die out the timing light stops flashing sometimes the idle will pick back up and the light starts flashing again and other times the timing light stops flashing and it dies ? I also pulled the fuel rail and put cups under each injector and there is no leak down or drips and they have good spray patterns.

Last edited:

Similar threads

- Replies

- 5

- Views

- 434

- Replies

- 1

- Views

- 218

- Replies

- 0

- Views

- 240