grumpyvette

Well-known member

one of my buddies stopped by with a minor exhaust leak that needed fixing, it took about 8-9 minutes and we had it fixed, the local muffler shop wanted a $100 to replace the NEARLY NEW exhaust pipe...

another friend I have dropped by last week with a busted bracket, that cost over $120 at the dealer but he can,t buy one since they are discontinued.....

yet another in a long line of reasons to own a decent welder.......

I can,t even imagine being in this hobby/obsession without at least a oxy-acetolene torch or a stick welder of some type.

heres a small sample, just remember these names

MILLER

HOBART

LINCOLN

HTP

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907335

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1297

http://www.welders-direct.com/merchant2/merchant.mv?Screen=CTGY&Store_Code=WD&Category_Code=MW

http://www.welders-direct.com/merchant2/merchant.mv?Screen=CTGY&Store_Code=WD&Category_Code=TW

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550

http://www.htpweld.com/products/mig_welders/mig_140.html

http://www.htpweld.com/products/tig_welders/tig201.html

heres an old post that cover much of the info, LOOK THRU THE LINKS

a decent arc or stick welder will do a good deal of whats likely to need welding, an oxyacetolene torch is versital, a mig is really easy to master and a good tig will handle about anything you can name plus aluminum

http://www.twi.co.uk/j32k/protected/band_3/jk6.html

TIG (Tungsten Inert Gas Welding)

basically youve got a controlable electric arc in a gas shield that you use similar to a oxy-acetolene flame to melt the material and feed a rod of similar material to flow and join the peices

This process is the toughest to learn. The electrode is composed of Tungsten, and a current is flowed through it controlled by either a foot pedal, a hand switch, or a fixed current on the machine itself. I am learning TIG using a foot pedal, the more you press down on the metal, the more amps you get. Once you get enough current flowing to get an appropriate sized weld pool, you start dabbing a filler metal into the puddle as you move the electrode further down the work piece. TIG allows you a great amount of control because you regulate how much current the electrode gets and how much filler metal the weld pool gets. This process is very slow compared to the other types though. in my opinion its by far the best process simply because you can CONTROL BOTH THE HEAT POLARITY AND MATERIAL FEED CONSTANTLY MAKING ADJUSTMENTS IN BOTH SHOULD YOU CHOOSE

MIG - (Metal Inert Gas)

http://www.twi.co.uk/j32k/protected/band_3/jk4.html

MIG is the easiest process of welding. A feeding gun is used to feed a spool of filler metal wire into the weld pool. in effect you feed a charged wire into the weld are where it melts on contact due to the current arc ,Current is usually switched on and off by means of a trigger on the gun. Amps are usually controlled by a dial on the MIG machine itself, meaning that you cannot adjust current in the middle of welding. Though, with some machine you are able to get a foot pedal to control Amps while welding.the better machines allow you to vary the speed of the wire feed but you set the electrical energy (heat with a dial), its extremely fast and simple to use but your basicall shooting molten wire into the area to be welded.

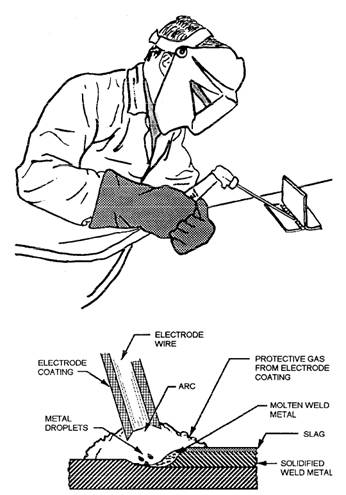

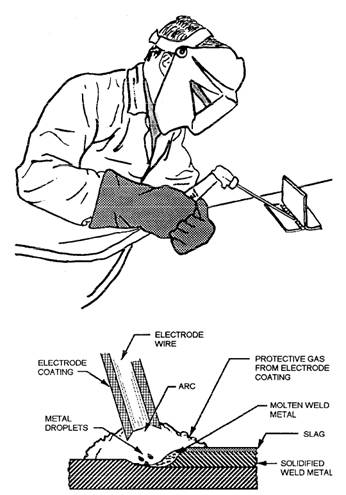

Arc Welding (stick)

Arc welding is mostly used in industrial applications. An electrode is used to strike an arc, the electrode then melts away to deposit metal into the weld pool. The electrode is coated with a variety of different materials which are used to help keep the weld pool from being contaminated.

TIG and non-flux-cored MIG both use a variety of different shielding gases to help keep the weld pool from being contaminated depending on what metal is being welding.

another friend I have dropped by last week with a busted bracket, that cost over $120 at the dealer but he can,t buy one since they are discontinued.....

yet another in a long line of reasons to own a decent welder.......

I can,t even imagine being in this hobby/obsession without at least a oxy-acetolene torch or a stick welder of some type.

heres a small sample, just remember these names

MILLER

HOBART

LINCOLN

HTP

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907335

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1297

http://www.welders-direct.com/merchant2/merchant.mv?Screen=CTGY&Store_Code=WD&Category_Code=MW

http://www.welders-direct.com/merchant2/merchant.mv?Screen=CTGY&Store_Code=WD&Category_Code=TW

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550

http://www.htpweld.com/products/mig_welders/mig_140.html

http://www.htpweld.com/products/tig_welders/tig201.html

heres an old post that cover much of the info, LOOK THRU THE LINKS

a decent arc or stick welder will do a good deal of whats likely to need welding, an oxyacetolene torch is versital, a mig is really easy to master and a good tig will handle about anything you can name plus aluminum

http://www.twi.co.uk/j32k/protected/band_3/jk6.html

TIG (Tungsten Inert Gas Welding)

basically youve got a controlable electric arc in a gas shield that you use similar to a oxy-acetolene flame to melt the material and feed a rod of similar material to flow and join the peices

This process is the toughest to learn. The electrode is composed of Tungsten, and a current is flowed through it controlled by either a foot pedal, a hand switch, or a fixed current on the machine itself. I am learning TIG using a foot pedal, the more you press down on the metal, the more amps you get. Once you get enough current flowing to get an appropriate sized weld pool, you start dabbing a filler metal into the puddle as you move the electrode further down the work piece. TIG allows you a great amount of control because you regulate how much current the electrode gets and how much filler metal the weld pool gets. This process is very slow compared to the other types though. in my opinion its by far the best process simply because you can CONTROL BOTH THE HEAT POLARITY AND MATERIAL FEED CONSTANTLY MAKING ADJUSTMENTS IN BOTH SHOULD YOU CHOOSE

MIG - (Metal Inert Gas)

http://www.twi.co.uk/j32k/protected/band_3/jk4.html

MIG is the easiest process of welding. A feeding gun is used to feed a spool of filler metal wire into the weld pool. in effect you feed a charged wire into the weld are where it melts on contact due to the current arc ,Current is usually switched on and off by means of a trigger on the gun. Amps are usually controlled by a dial on the MIG machine itself, meaning that you cannot adjust current in the middle of welding. Though, with some machine you are able to get a foot pedal to control Amps while welding.the better machines allow you to vary the speed of the wire feed but you set the electrical energy (heat with a dial), its extremely fast and simple to use but your basicall shooting molten wire into the area to be welded.

Arc Welding (stick)

Arc welding is mostly used in industrial applications. An electrode is used to strike an arc, the electrode then melts away to deposit metal into the weld pool. The electrode is coated with a variety of different materials which are used to help keep the weld pool from being contaminated.

TIG and non-flux-cored MIG both use a variety of different shielding gases to help keep the weld pool from being contaminated depending on what metal is being welding.