jims427400

Well-known member

- Joined

- Jun 7, 2005

- Messages

- 763

- Location

- Temperance Michigan

- Corvette

- 67 427 tripower,68 427 tripower,04 Z16, 62 340hp

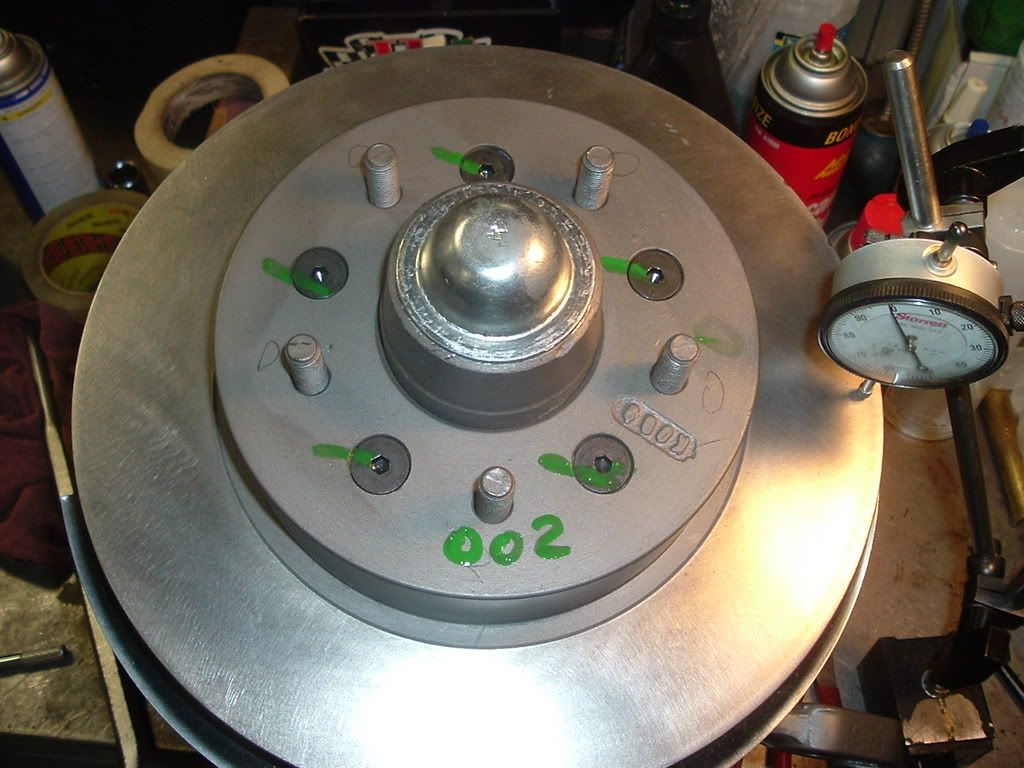

What is the best way to remove the rivots from the original rotors??

The rears were already removed.

Do I grind or chisel??

Jim

The rears were already removed.

Do I grind or chisel??

Jim

Steve

Steve

Art

Art