This one is pretty much like the one in my car

GM 350 A/T FLYWHEEL 168 T 12-14 PITCH DIAMETER 14.13"

GerryLP

GM 350 A/T FLYWHEEL 168 T 12-14 PITCH DIAMETER 14.13"

GerryLP

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello everyone,

I'm doing a body off resto on my 81 corvette. But to go to the subject..

My L81 engine has been redone inside and out. No major changes. The crankshaft was to far gone so i have a new one (still a 350) new pistons, a new Comp Cams cam, 1 new valve a new high flow oilpump and al the normal small things. I would like the have the outside of the L81 close to original but i don't have any picture's and i can't find them anywhere.

I put on some sparkplugshielding, i like them but i don't know if these are OEM or not?

If someone has picture's of a OEM L81 please post or email them so i can look for variable's between the two.

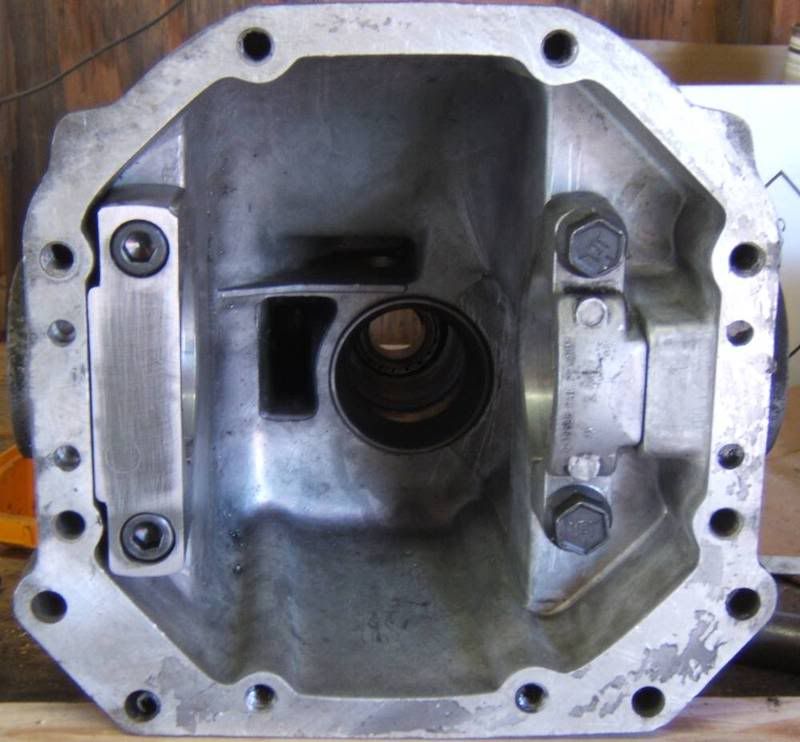

Here are some pictures of my L81 still in progress...

Greetings Peter.

Hello Jon,

Sorry for the late reply! And yes that is GM blue (so not the original L81 blue).

Greetings Peter

otfl And there is more to come!

otfl And there is more to come!