Bill75

Well-known member

- Joined

- Jan 1, 2004

- Messages

- 698

- Location

- Somers CT

- Corvette

- 75 Coupe ZZ4, Brodix IK-180's, Headers,TK0-500

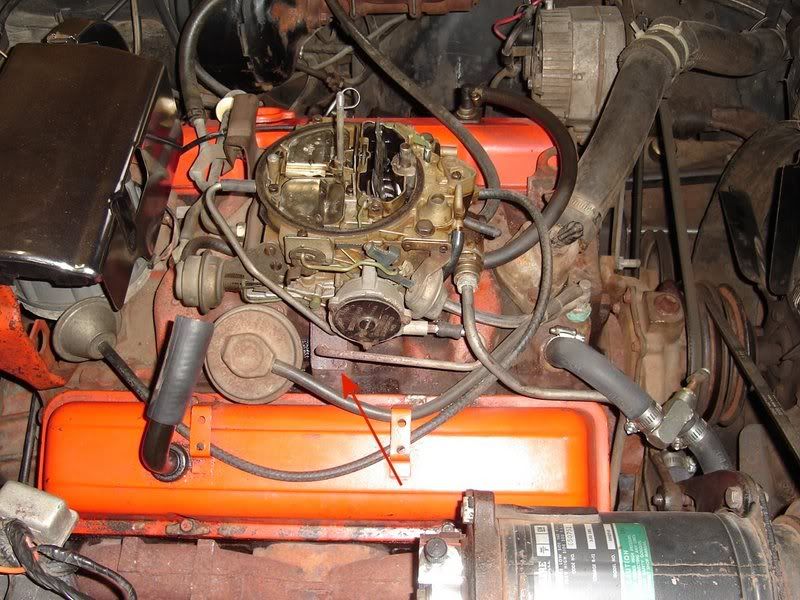

I had to do away with the perfectly working mechanical choke on my Q-Jet when I switched to this ZZ4 motor so I replaced it with an electric one that's never worked worth a darn. I think the housing with the bi-metalic spring I have is made by Edlebrock, it has the number 3182A on the outside.

I've set it up properly but it only wants to open about 1/2 way no matter how long the engine runs. I'm getting 12volts to the unit ok, I wired it to the wiper motor feed and the mechanical linkage appears to be functioning properly, just seems like the bi-metalic spring inside isn't traveling far enough to complete the job.

Is there anything out there that WORKS RELIABLY that someone could recommend?

Thanks

I've set it up properly but it only wants to open about 1/2 way no matter how long the engine runs. I'm getting 12volts to the unit ok, I wired it to the wiper motor feed and the mechanical linkage appears to be functioning properly, just seems like the bi-metalic spring inside isn't traveling far enough to complete the job.

Is there anything out there that WORKS RELIABLY that someone could recommend?

Thanks